Vibro Sifter Manufacturers

Vibro Sifter Manufacturers

Having 20 years of experience has been prosperously blooming in the realm of engineering industries.

All the pharmaceutical equipment are used in pharmaceuticals needs to be the highest standards as they are associated with the human health and Abster known it bitterly hold more than 14 years of experience in the manufacturing of pharmaceutical equipment and having two manufacturing unit respectively at Ahmedabad. We as pioneer Pharmaceutical machine manufacturer machine like IPC Bin, Vibro Sifter, Bin Blender, Industrial Stirrers, Multi mill, Octagonal Blender,SS Double Cone Blender, Ribbon Blender, Storage Tank and Vessels, V Blender, IBC container etc. many more which are highly utilized in the Pharmaceutical, food , chemical, cosmetic industries for storage, blending stirring etc. many more. Fostering the latest technological advancement and innovation we have been able to score a paramount presence in the industry. Jaliyana is a reckoned name in the sphere of designing and manufacturing latest technology based process equipment. Due to the wide range of the product available with us we have been able to ensure that the all pharmaceutical equipment is best in class.

Vibro Sifter Exporters

Our superior quality range of equipment is well accredited by our global client for their high efficiency and long lasting performance. Every single unit of this pharmaceutical equipment is made from the AISI 316, AISI 304 top grade SS materials to ensure flawless and excellent performance. These all equipment is made from fine quality equipment under the effective supervision of our production engineers. These machines being designed in accordance with current industrial standards have high performance, uniform finish, durability, efficiency, sturdy design and dimensional accuracy. Our organization hold ISO certification and the product are developed cGMP, GMP standards.

We have achieved remarkable success in our domain under the efficient guidance of our organization head. His intense focus in maintaining long term ethical relation by supplying supreme quality product have awarded by vast clientele base to serve. To strengthen with client and to retain our valued customer we never compromise with the quality norms. Our highly skilled and technically efficient work force leads us to provide the best possible outcomes to the industry for maintaining an inimitable status in the global market.

Vibro Sifter Manufacturer in India

OUR VISION

To become a world famous manufacturer by rendering unmatched quality product range to the respective industry.

OUR MISSION

To become a trusted partner of the pharmaceutical industries by providing the cutting edge and best in class quality product, equipment & furniture.

OUR QUALITY

Our entire product range is made following international quality regulations and also thoroughly examined against different quality measures.

PHARMACEUTICAL EQUIPMENT MANUFACTURER IN INDIA

Vibro sifter

Bin Blender

Double Cone Blender

Storage tank and vessels

V Blender

Multi mill

IPC Bin

Vibro Sifter Manufacturer

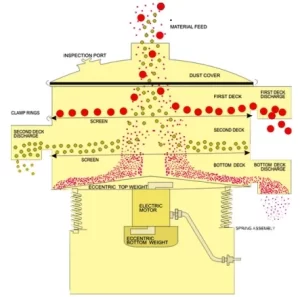

First thing to be known that Vibro sifter is also popularity known as Gyro screen. Vibro sifter which ensures the correct product quality of powders or liquids is achieved by removing oversize contamination. Vibro sifter is designed on the principle of the Gyratory motion and one of the most versatile and universally adaptable machines working across spectrum of industries. Vibro sifter in India carry out various duties including Screening and powder or granules sifting or classification, removal, dust removal from powder, granules, solid, liquid, separation filtration, syrup or oil, fiber/ husk recovery from liquid stream.

Working of Vibro Sifter Machine

- The working of the machine starts the process only after the materials is poured in the separator on a feeding hopper of the machine and before the start of the machine make sure that the base frame, cover and screen structure are all tightened with the clamping rings.

- The next step is to switch on the power from the electricity source. This apparently causes the motor to generate energy which instead enables it to vibrate as a result of off-balance weight assembly.

- Moreover the granules placed on the hopper then move across the sieves and passes through the same depending on the necessities.

- The equipment features exit components which discharge the materials after the particles travel in a regulated pathway.

- This happens right after successful separation of materials such that the larger ones are discharged in a separate container from the smaller ones.

- The size of the particle depends on the size of the permeable screens

- Once the entire process is completed and the process can again start all over

Material Processing of Vibro Shifter

We the design the machine in order to achieve the multiple plane vibration by suitable assembly of the specially designed Vibratory motor that is having peculiar weight at the top and bottom ends of the motor shaft. In our offered vibrosifter the motor is enlarged upright at the centre of the screening congregation, on a circular base by means of springs which permit the unit to vibrate freely. Further the installed springs absorb the vibrations and prevent them to be transmitted on the floor.

We offer various types of Vibro shifter and Vibro screen. Our esteemed clients flourished across globally can avail Vibro shifter at the most affordable price. It thus implies that the design of this equipment is to help in achieving the right product quality by eliminating oversize granules.

Moreover the offered machine is ideally suggesting the primary function of the machine which is used to separate and grade diverse sizes of particles.

In other instances, customers can find that some people refer to this accessory as:

- Safety screener

- Vibro sieve

- Control sieves

- Vibrating sifter

- Check screen or

Special features of Vibro sifter

Now a day, there are huge numbers of vibrating material separating machines are accessible in the market today. Our brand name products are esteemed among the clients and not only guarantee success in the material processing requirements. The below mentioned are the few features of Vibro Shifter machine to consider before purchasing it:

- Easy to operate

- Available of multi deck

- Simple and compact construction

- Less maintenance cost

- Less power consumption

- Faster separation due to spring

Uses of Vibro Sifter

Vibro sifter or vibro screen are used by industries like pharmaceutical, Agro , Agro processing, chemical, China clay, food , Dyes, Mines and minerals, powder processing plastic, PVC Petrochemical, paper and many more.

Application of Vibro Sifter

As, our manufactured machine is hugely well-known in the pharmaceutical market for screening, sieving, grading for solid-liquid separation, process to separate the desired elements and the undesired element from the combination of solid to solid and solid to liquid material. Our machines are hugely found in various industries such as Pharmaceutical, Chemicals, Cosmetics, Plastic, minerals, rubber compounds, metal powders, detergents, pesticides and fertilizers, dyestuff and pigments.