Ribbon Blenders & Mixers – Salient Features and Applications

Ribbon blender doesn’t need an introduction in the blending and mixing industry as it is one of the most sought after machines to carry out this crucial job. If you are looking for a blender that offers seamless, hassle-free and homogeneous blending and mixing experience, then ribbon blender is the one to go for. In this post, we will shed light on some of the salient features and applications of the ribbon blender, but before that let’s understand what this machine exactly is.

Ribbon blender doesn’t need an introduction in the blending and mixing industry as it is one of the most sought after machines to carry out this crucial job. If you are looking for a blender that offers seamless, hassle-free and homogeneous blending and mixing experience, then ribbon blender is the one to go for. In this post, we will shed light on some of the salient features and applications of the ribbon blender, but before that let’s understand what this machine exactly is.

Introduction to Ribbon Blender

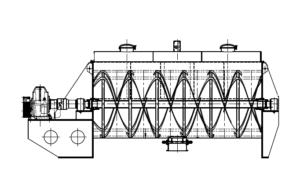

Ribbon Blender Machine Manufacturers

Designed for unparalleled blending and mixing, the ribbon blender is considered a great pick for blending a number of materials such as pellets, granules, paste, fluids and talcum powder. You can expect the highest degree of efficiency and accuracy with this blender. Thanks to its design and construction! This high end machine comprises of a U-shaped horizontal trough. There is also a single or double ribbon agitator in the machine that rotates.

You definitely need a ribbon blender, if you are looking for a machine that empowers your blending business with exceptional blending and mixing capabilities. Let’s take a quick glance at some of the salient features of the ribbon blender.

Salient Features of Ribbon Blender

High speed and efficient blending capabilities

Ribbon blender is known for its triple ace mixing capabilities. Due to this action, you can achieve highly efficient mixing at high speeds. You will find double helical agitators inside rotating inside and that makes tumbling of the material easy inside the blender.

Performance and no frequent breakdowns

This machine features a double ribbon agitator due to which the machine becomes capable of blending a number of materials in powder and viscous forms. You can even blend liquids using the ribbon blender. The best part is the radial speed of the ribbon which is pretty flexible and that makes your job a cake-walk. You will hardly see any breakdowns with this machine and it is known for exceptional performance.

Phenomenal loading rate and sealing capabilities

One of the major highlights of the ribbon blender is its superior loading rate. And that’s not it. It also boasts of great sealing capabilities. You will find the mixing cylinders angling between 180 degrees to 300 degrees that makes this machine capable of such loading rate which is as high as 70 percent. You can also pick from a number of sealing methods facilitated for your convenience.

Homogeneous mixing capabilities

As stated earlier in the post, the ribbon blender has a double ribbon agitator. The materials inside the blender are moved in a countercurrent motion. Due to this they are displaced from one end to another in a seamless fashion. You can expect homogeneity of the highest level with the ribbon blender.

Superfast rotational speed

Besides, all of the other capabilities we have mentioned so far, this amazing blender also features a superfast rotating speed between 70 to 100 meters per minute. This helps provision high radial and lateral functioning in pretty short cycles. You will be surprised that the entire blending gets finished within 15 to 20 minutes.

Doesn’t occupy much space

If you are facing space related issues then you must certainly go for the ribbon blender as this blender doesn’t need much of overhead space.

Numerous working capacities

This multi-purpose blending and mixing machine offers a number of working capacities. They come in variable sizes ranging from 5 liters to a whopping 25,000 liters. The minimum working capacity of the ribbon blender is no less than the 30 to 40 percent of the overall capacity which makes it an obvious choice for various industries and applications; we are going to talk about now.

Applications

Seamless mixing of drugs, cosmetics and other materials.

Dry blending of capsule ingredients.

Suitable for the blending of dry solids.

Dry granules and pellets in huge volumes can be lubricated quite easily.

Ideal for the manufacturing of polymer blends, composite fillers and pharmaceutical powders and thus making this machine an obvious choice for pharmaceutical manufacturing purposes.

Used for blending infant food, dried food products, cereals, dietary supplements and instant drinks in the food & beverage industry.

It can be easily concluded that the ribbon blender and mixer can just not be done without. If you need more information about various mixers and blenders, feel free to write in to us.