Lab Sigma Mixer

Lab Sigma Mixer is compact model mixer suitable for small batches production having usage in research labs, institutes. Machine also uses in industrial application where high value products to be processed in small batches. Machine completely manufactured from Stainless Steel 316 materials with sturdy structure. We manufacture Lab Sigma Mixer in capacity ranging from 5 kgs. Up to 50 kgs.

Lab Scale Sigma Mixer is used for mixing and kneading for mixing, kneading of highly viscous mass, sticky and dough like products, Mixing of pastes, rubber, and heavy plastic masses, applications in Food, Rubber, Pharmaceutical, Chemical and agro industries, Dry powder to wet phase mixing. This mixer is most suitable for highly viscous material and dough like masses.

The laboratory model Double Sigma Mixer batch systems provide complete, homogeneous mixing, even in small quantities.

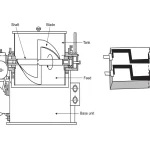

The vessel and moving parts inside are designed to ensure consistent granulation action, and a predictable homogeneous blend in a broad range of products. A special breaker ensures movement of elements to eliminate dead spots and ensure all material are blended thoroughly and granulated consistently.

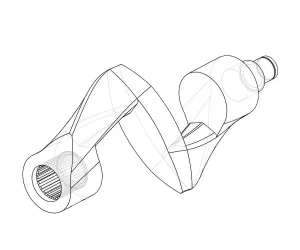

The Lab sigma Mixer is a twin basin kneading machine with two horizontally arranged kneading blades, which are deeply geared into one another and strip themselves reciprocally. Each blade moves the material in opposite direction thereby providing excellent cross mixing of all raw materials. The blades pass the trough walls and each other at close clearances resulting in good mixing. The close clearance produces a shearing and tearing action that is beneficial to the size reduction of solids. Selection of appropriate blade shape and speeds result in excellent mixing.

Hydraulic tilting system is provided with complete power pack, electric motor, pressure valves, pipes, fittings, cylinders and hoses which makes the tilting mechanism quick, easy and simple to operate.

Working Principle Sigma Mixers

The Sigma Mixer bowl is made of heavy steel plate making it a rugged heat proof unit. This is especially useful for bulky material and additional thinning prior to discharge. Tangential blades are supplied with differential speeds. Heavy duty machine cut spur gears are provided. Spherical type bearings are provided at both the ends to suit both radial and thrust load. Gland type shaft seals are fitted at both the ends for easy maintenance.

Sigma Mixer Bowl is provided with jacket for temperature control and adoptable for cold water or brine or hot water, steam etc. Mixers can be designed for vacuum operations. Sanitary construction is provided for food and pharmaceutical procedures.

Manually operated discharge system is provided for lab models and motorized discharge system is provided for plant models.

| Type | SM-5 | SM-10 | SM-100 | SM-300 | SM-500 | SM-1000 | SM-1500 | SM-2000 | SM-3000 | -4000 | SM-5000 | |

| Volume (L) | 5 | 10 | 100 | 300 | 500 | 1000 | 1500 | 2000 | 3000 | 4000 | 5000 | |

| Rotation Speed (Rpm) | 3323 | 3323 | 3522 | 3721 | 3721 | 3525 | 3016 | 3016 | 3827 | 3827 | 3827 | |

| Main Motor Power (Kw) | 0.75 | 101 | 3-75 | 11-30 | 15-37 | 22-90 | 22-90 | 30-100 | 30-110 | 45-110 | 55-132 | |

| Heating Methods | Steam Pressure(Mpa) | 0.3 | ||||||||||

| Electric Power(Kw) | 1 | 1 | 4 | 9 | 16.2 | 27 | 32.4 | 40 | 72 | 72 | 96 | |

| Vacuum (Mpa) | -0.094 (acuum Kneader) | |||||||||||

| Pressure (Mpa) | 0.45 (Pressure Kneader) | 0.35 (Pressure Kneader) | 0.30 (Pressure Kneader) | |||||||||

| Weight (Kg) | 300 | 400 | 1250 | 1600 | 3000 | 4500 | 5800 | 6500 | 11000 | 13000 | 21000 | |