Ribbon Mixer Working Principle: A Guide to Blending

Ribbon Mixer working principle ; In an Pharmaceutical – A pharmaceutical Ribbon blender is a very important Equipment in the drug-production industry. There are different types of blenders in pharmaceuticals – although they are similar in function. This blending related article focuses on type of pharmaceutical blender machine – the ribbon blender. You will get to know what is a ribbon mixer, the details about this device, the benefits you stand to gain, and some of the variations available.

What is a ribbon blender?

The Pharmaceutical ribbon blender also called as Double Helical Ribbon mixer. It is used to mix and Blend dry solid and semi-solid raw materials such as powders, pastes, and dried granules. It is an Versatile and efficient and Equipment used in various sectors, including the pharmaceutical, chemical, cosmetics, food, and agricultural industries.

The ribbon blender mixer is a type of gentle to vigorous mixer. It has a Helical mixing blade that ensures that the raw materials are mixed through controlled motions. The Helical mixing blades are fully sealed at each end to avoid leakage, making them appropriate for dry powders and semi-liquid materials.

Ribbon Mixer WORKING PRINCIPLE

Before diving further let us understand how a ribbon blender works and how they homogeneously distribute materials.

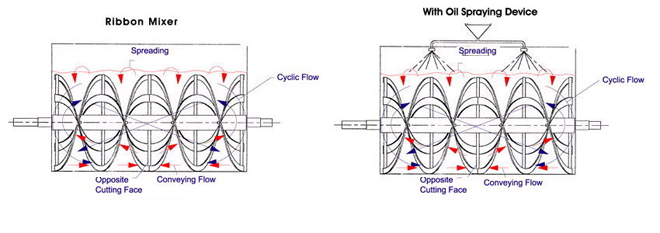

Ribbon blenders are convective mixers. It consists of a horizontal “U” Vessel with a horizontally installed shaft.

The ribbon is made in two parts –

The outer helix moves the material from both ends of the vessel towards the centre, and

The inner helix transfers the material towards both ends, performing a sort of convective mixing.

The mixture movement is forced by the rotation of the ribbon which is circulating the product in two directions. After mixing it for enough time, those 2-axial movements, coupled with some radial movement of blades “cutting” the material when rotating, allows it to reach the required degree of homogeneity.

FEATURES OF RIBBON BLENDERS

These quick, effective and top-quality ribbon blenders have securely controlled clearances between surfaces and agitator tips which help them mix ingredients evenly without damaging.

Apart from the above, ribbon blenders have few more advantages that prove them to be more effective and efficient than the other mechanisms and machines.

- Simple and robust design

- Multipurpose mechanism

- Clean and hygienic

- Homogeneity

- Time-saving

- Consistency

- Heating and cooling

- Applicable to various industries such as agro, cosmetics, pharmaceuticals and food