Sigma Mixer – Design, Construction, Operation, Applications

Sigma Mixer- Design & Construction Operations and Applications Explained

Sigma Mixer is highly popular equipment used for efficiently mixing and kneading high viscosity materials with utmost ease. Since, sigma mixer comes from the double arm kneader mixer family. So, let’s take a quick look at the design and construction of double arm kneader mixers.

Design of Double Arm Kneader Mixer

Double arm kneader mixers consist of two mixing blades which are positioned in a horizontal W shape. There is a wide array of blades made available such as masticator blade, sigma blade, spiral blade and nabbed blade to name a few. The gyratory motion of these blades takes place in two ways. One is peripheral motion to each other and the one other in which the blades inside the furrow can stretch outwards. The blades may operate at the same or different speeds while moving towards each other. The blades go over the container walls and each other at very close clearances of 2-3 mm which helps produce a homogenous mix.

The biggest benefit of such close clearances is high shearing action which easily reduces every single large size particle. A consistent particle size distribution can be achieved within a very short span of time which is as less as just 10 to 30 minutes. High homogeneity levels can be expected while using these mixers. You can expect upto 99 percent of homogeneity which is amazing in itself. These mixers also come with their variants such as double arm kneader mixer extruders and they are very much capable of handling highly viscous materials. Even materials with 10 million centiposes viscosity can be managed.

Operation of Sigma Blade Mixer

Now, let’s take a quick look at how sigma blade mixer operates. Material is loaded from the top of the container, but it is mostly just about 40 to 65 percent of the total volumetric capacity of the mixer. Heavy duty drive systems are in place to facilitate the rotation of blades. These systems comprise a gearbox, motor, gears and couplings.

Usually the tip speed of a sigma mixer is kept to 60 metres/minute. The mixing process may take place either at room temperate or controlled temperature conditions. Provision of jackets is there for the circulation of hot or cold media which comes in handy to maintain the required temperature. You can also equip the mixer with a discharge arrangement. The most commonly seen discharge arrangement is tilting discharge. Tilting arrangement of the container is designed for manual, motor or hydraulically operated arrangement.

For materials containing lower viscosity, a bottom discharge valve can be facilitated on the trough. It is flush with a mixer trough to keep at bay any sort of dead or unmixed pockets of material.

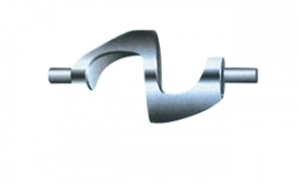

The sigma blade profile is shown in figure 1.

Figure 1 – Sigma Blade

In mixers handling very viscous materials, it is necessary to promote both lateral and transverse motion of the material. The geometry and profile of the sigma blade is designed such that the viscous mass of material is pulled, sheared, compressed, kneaded, and folded by the action of the blades against the walls of the mixer trough. The extent to which this happens depends on the action of the blades – tangential or overlapping and the ratio of the speed of rotation of the blades.The helix angle of the blade can be modified depending on the required shearing.

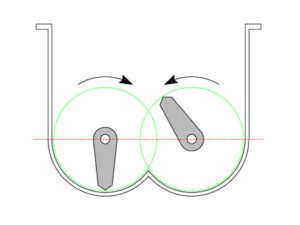

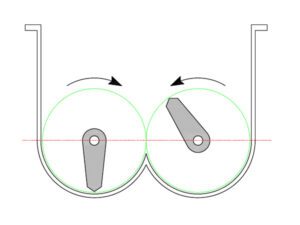

Tangential and Overlapping Blade Action

Figure 2 – Tangential Blades

In the tangential design, the blades rotate in the trough meeting tangentially as shown in figure 2. The front blade generally rotates faster than the rear blade usually in the ratio of 3:2. Tangential blades are generally used for material of higher viscosities such as adhesives, rubber compounds, flush colors, dyes, and pigments.

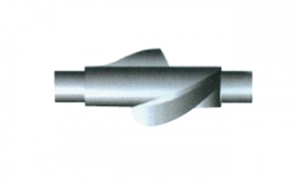

Figure 3 – Overlapping Blades

In the overlapping design, the blades overlap above the saddle of the container. The overlapping blade configuration is shown in figure 3. Due to the overlapping action it is necessary that the relative position of the two blades is unchanged, and as a result, both the blades rotate at the same speed. Materials that flow freely or creep down into the blades are mixed using the overlapping blade action. This design offers a faster interchange of material from one blade compartment of the mixer to the other. Overlapping blade action is used for materials of lighter viscosities such as carbon pastes, clay coating, creams, and ointments. The overlapping blade produces a lower kneading and shearing compared to the tangential blade action.

Applications of the Sigma Mixer

The sigma mixer is the best suited mixer for pasty, sticky, and gritty slurries with high viscosity. The following are some of the commonly used products that are mixed in the sigma mixer

- Adhesives

- Biscuit dough

- Explosives

- Fiberglass resin doughs

- Food and confectionery products

- Gaskets and gland packings

- Grinding wheel preparations

- Hot-Melts

- Metal powders

- Butyl rubber

- Carbon pastes

- Ceramics

- Chemicals

- Chewing gum

- Crayon and pencil lead

- Inks and pigment products

- Marzipan

- Mastics

- Sugar pastes

- Moulding preparations

- Pencil erasers

- Pharmaceuticals

- Plastics

- Putties

- Refractories

- Sealing compounds

- Silicone rubber

- Soaps and detergents

- Solid propellants

Sigma Blade Designs