How Plough Share Mixer Works?

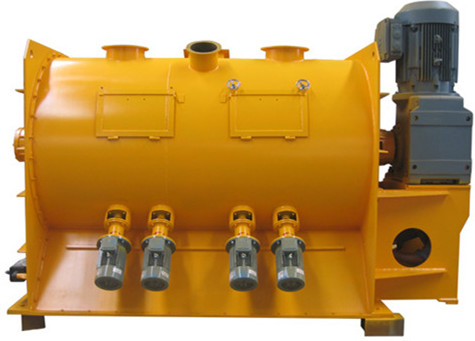

Plough mixer is widely used to mix powder, granule, and small liquid additives in food, chemical, and construction line. Plough Shear Mixer has different name in different area. In America, people name it as plow mixer, In Europe, people like to name it Ploughshare mixer.

The working principle of plough shear mixer:

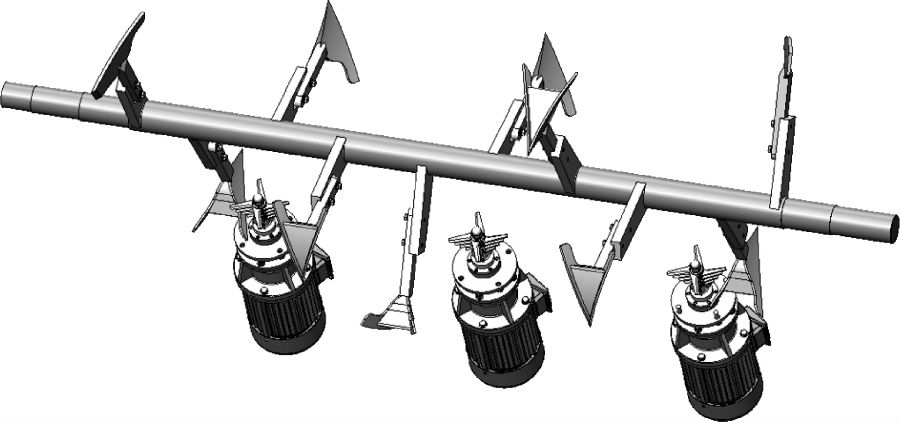

It has a cylindrical shell with plough shovel welded or bolted on arms and the shaft runs at high speed to effect a fluidizing action. Plough Shear Mixer is designed for heavy duty blending of both dry and wet materials. Plough shape shovels mounted on a central shaft with its pointed ends are easily penetrable through the dense powder, party mass. The over lapping of shovels coupled with its shape and the high speed of the ploughs produces good mixing action and high turbulence. The use of high speed choppers further reduces the product particle size thus resulting in a better mix. The plough shovel lifts the material upward, and the material settles in a pattern. Whirling, three-dimensional product movement makes output material with very high homogeneity within short mixing time.

Plough shear mixer is particularly good at handling bulk powder in dry / dry solids, dry / wet paste, and wet-wet mass of food additives, mortar, fertilizing, sludge, plastic, and special building material. The powerful shearing effect makes it high efficiency, and good mixing result.

Feature:

1. Optional Teflon coated internals for food and sticky material applications

2. Available in all grades of Carbon Steel and Stainless Steel

3. Optional wear resistant linear plates provided for abrasive products

4. Jacketed construction available for steam and cooling applications

Advantages of Plough Shear Mixer machine , Ploughshare mixer

- High Speed and Homogenous Mixing & Drying

- Wide Range of Application

- Short Mixing & Drying Time

- Easy to Clean

- Avoid Agglomerations

Standard Features of Plough Shear Mixer – Ploughshare mixer

- Batch Capacity range from 100-30000 Liter

- Mild Steels /Stainless Steels constructions

- One end welded and one end bolted

- Temperature and Pressure for mixer & drying

- Gears Reducer Motor

- Mechanical seal / Gland Packing Seal + Air Purge Seal

- Pneumatic Operated Outlet Valves

Ploughshare Batch Mixer

Special Features of Plough Mixer Machine – Ploughshare mixer

- Multiples designs for plough shovels (ploughs with teeth, end scraper)

- Petal type choppers, knife type choppers

- Vacuums/Pressure inside mixers

- Heating/Cooling with Jackets for mixers

- Spraying Nozzles for liquids

- Various Outlet Valves depend on customer’s process requirements

- Heavy duty drive units

- Flameproof / Explosion-proof for electricity

- Electricals Control Panel system

- GMP manufacturing / FDA Standards

Application of Plough Mixer – Ploughshare mixer

Ploughshare mixer batch plough shear mixer & drying , Liquid Spraying , Vacuum with Quick versatile mixer & Drying available with an extensive range Ploughshare mixer of Wide range applications:

- Dry powders mixing

- Paste mixing & Dryer

- Mixing of wet slurries

- Wet granulations

- Powders and granules Liquid coating

- Fat and oil incorporations

- Vacuum drying Systems

Technical Specification of Plough Shear Mixer

| Model | Gross Volume | Working Volume | Speed (RPM) | Motor Power |

| PM-100 | 100L | 40-60L | 101rpm (shaft) 1440rpm (chopper) |

3KW 1.5KW x 2 |

| PM-300 | 300L | 120-180L | 85rpm (shaft) 1440rpm (chopper) |

4KW 1.5KW x 2 |

| PM-500 | 500L | 200-300L | 85rpm (shaft) 1440rpm(chopper) |

7.5KW 1.5KW x 2 |

| PM-1000 | 1000L | 400-600L | 85rpm (shaft) 1440rpm (chopper) |

11KW 4KW x 2 |

| PM-1500 | 1500L | 600-900L | 85rpm (shaft) 1440rpm (chopper) |

15KW 4KW x 2 |

| PM-2000 | 2000L | 800-1200L | 85rpm (shaft) 1440rpm (chopper) |

18.5KW 4KW x 3 |

| PM-3000 | 3000L | 1200-1800L | 57rpm (shaft) 1440rpm (chopper) |

18.5KW 4KW x 3 |

| PM-4000 | 4000L | 1600-2400L | 57rpm (shaft) 1440rpm (chopper) |

22KW 4KW x 4 |

| PM-6000 | 6000L | 2400-3600L | 57rpm (shaft) 1440rpm (chopper) |

30KW 4KW x 4 |

| PM-8000 | 8000L | 3200-4800L | 42rpm (shaft) 1440rpm (chopper) |

45KW 4KW x 4 |

| PM-10000 | 10000L | 4000-6000L | 33rpm (shaft) 1440rpm (chopper) |

55KW 5.5KW x 5 |

| PM-12000 | 12000L | 4800-7200L | 30rpm (shaft) 1440rpm (chopper) |

55KW 5.5KW x 5 |

| PM-15000 | 15000L | 6000-9000L | 30rpm (shaft) 1440rpm (chopper) |

75KW 5.5KW x 5 |

| PM-20000 | 20000L | 8000-12000L | 30rpm (shaft) 1440rpm (chopper) |

90KW 5.5KW x 5 |